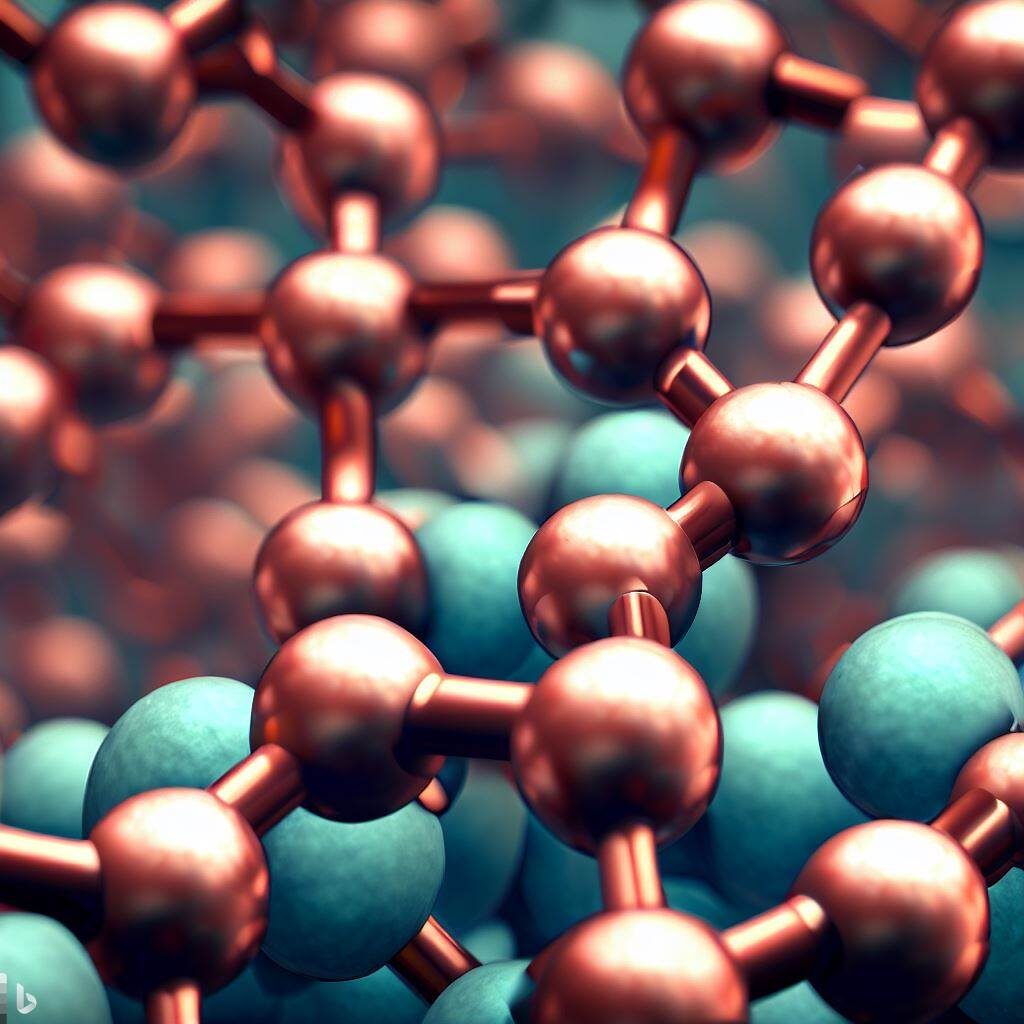

A recent study investigated a new coating for medical catheters that could help prevent inflammation and infection. The coating combines chitosan, a natural antibacterial polymer, with copper ions, which have anticoagulative and antiproliferative properties. The researchers developed chitosan-copper (Chitosan-Cu) coatings at three different ratios and tested their cytotoxicity, or potential to damage cells. The results showed that a coating with a 10:1 Chitosan:Cu ratio had no toxic effects and high cell viability, indicating it is safe for medical use.

Medical catheters are commonly used for delivering fluids or medications, as well as draining bodily fluids. However, their use also carries risks of infection, inflammation, and blood clot formation. Coatings that can mitigate these risks without being toxic have been sought after. Chitosan is a natural and antibacterial polymer, while copper ions have been shown to prevent blood clotting and cell overgrowth. A combination of chitosan and copper in a coating could provide an effective solution.

What are the application areas of Chitosan-Cu coating?

This Chitosan-Cu coating could have applications in several medical areas, including:

• Intravenous catheters – As the study focused on, coatings that prevent infection and blood clotting are useful for IV catheters to improve safety. The coating could help extend the functional lifetime of IV catheters and reduce adverse events.

• Urinary catheters – Urinary catheters also carry risks of infection and inflammation, so antibacterial and anticoagulative coatings would be beneficial. The coating may allow urinary catheters to remain implanted for longer durations by mitigating biofouling and clot formation.

• Central venous catheters – Central venous catheters inserted into major veins for long periods also frequently lead to infection and other complications. The coating could significantly improve safety, especially for long-term central venous access.

• Dialysis catheters – Dialysis catheters used for hemodialysis access are prone to infection and thrombosis, and allowing extended use could reduce medical costs and patient burden. The antibacterial and anticoagulative properties of the coating may decrease adverse events for dialysis patients requiring frequent access.

• Surgical sutures – Surgical site infections remain a major concern, and coated sutures could help prevent bacterial colonization and promote wound healing after surgeries. The coating may be useful for internal sutures that cannot be easily removed, while remaining non-toxic.

• Stents – Coronary stents and other implants that remain permanently in the body can also become infected or lead to blood clots. A safe and durable coating may extend the long term functionality of stents and other implants.

• Wound dressings – In addition to medical devices, the Chitosan-Cu coating could be applied to wound dressings, bandages, and other materials that come into direct contact with the body. This could help avoid infections, promote healing and reduce inflammation for injuries, burns and surgical wounds.

• Other devices – Essentially any medical device that is at risk of causing infection or clotting due to contact with bodily fluids could potentially benefit from this type of coating, if further research shows it to be safe and effective for a given application. The versatility of the coating across different materials suggests its usefulness for various medical devices.

The researchers tested three Chitosan:Cu ratios of 10:1, 50:1 and 100:1 to determine an optimal ratio that is bioactive but non-toxic. They applied the coatings to silicone rubber and tested them using fibroblasts. After 24 and 72 hours, all coatings showed high cell viability, above 100%, indicating no toxicity. The 10:1 ratio showed the highest increase in cell growth after 72 hours. Surface analysis confirmed the presence of copper ions in the 10:1 coating, suggesting it retains bioactivity.

Previous studies have shown that a 10:1 Chitosan:Cu ratio has antibacterial and anticoagulative properties. The present study found this ratio to also be non-toxic, highlighting its promise for medical applications. The researchers conclude that copper at up to 10% in the Chitosan-Cu coating is safe and suitable for further research.

The results are promising for the use of Chitosan-Cu coatings, especially at a 10:1 ratio, to produce medical catheters that are bioactive yet non-toxic. With further research, these coatings could help reduce risks of infection and improve safety for patients requiring catheter use. The study demonstrates the potential for natural and metallic materials to be combined for medical applications in a safe and effective manner.

What is chitosan-copper complex?

A chitosan-copper (Chitosan-Cu) complex refers to copper (Cu) ions that are bonded or chelated to chitosan molecules. Chitosan is a natural polymer derived from chitin, with many amino and hydroxyl groups that can bind metal ions like copper. Forming a complex with copper ions gives chitosan new properties, including:

• Enhanced antibacterial activity. Copper ions have natural antibacterial properties and can boost the antibacterial effect of chitosan when combined. The Chitosan-Cu complex can act against a wide range of bacteria, including antibiotic-resistant strains.

• Anticoagulative effects. Copper ions are able to inhibit the enzymatic activity involved in blood clot formation. By chelating copper ions, chitosan gains anticoagulative properties which can help prevent blood clot formation on surfaces. This is useful for medical devices like catheters that contact bodily fluids.

• Reduced cell adhesion and proliferation. Copper ions have been shown to decrease the adhesion and growth of cells on surfaces. A Chitosan-Cu complex can help prevent excess cell attachment and proliferation on medical implants or wounds.

• Improved wound healing. While preventing excess cell growth, copper ions are also able to stimulate the proliferation of fibroblasts and keratinocytes important for wound healing at lower concentrations. A Chitosan-Cu complex could help promote healing while reducing scar formation.

• Extended device lifetime. By preventing infection, clot formation and excess cell adhesion, a Chitosan-Cu coating could allow medical devices like catheters to function for longer periods with a lower risk of complications. This could reduce costs and inconvenience for patients.

• Versatility. Chitosan provides a versatile, biocompatible matrix for chelating and immobilizing copper ions. The Chitosan-Cu complex can be applied as a coating to various medical device materials including silicone, polyurethane and latex. It can also be used for wound dressings, sutures and other applications.

The properties of the Chitosan-Cu complex depend on the ratio of chitosan to copper, with higher copper concentrations having stronger bioactivity but potential toxicity. Optimizing this ratio is important to achieve safe and effective antibacterial, anticoagulative and anti-proliferative effects for medical applications. The complex also needs to be durable and non-toxic, especially for implanted devices or wound healing.

While chitosan and copper each have useful properties, forming a complex between them provides new opportunities for improving medical device safety, reducing infection risk and aiding wound healing. The Chitosan-Cu complex is a promising material, but requires more research to determine safe and effective uses for real-world clinical applications.

The Chitosan-Cu coating developed in this study is made from two main raw materials:

• Chitosan – Chitosan is a natural polysaccharide derived from chitin, which is found in the exoskeleton of crustaceans like shrimp and crabs. Chitosan is biodegradable, biocompatible and has natural antibacterial properties, making it useful for medical applications. To form the coating, chitosan is dissolved in acetic acid to create a chitosan solution.

• Copper sulfate (CuSO4) – Copper sulfate is used as a source of copper ions (Cu2+). Copper ions have anticoagulative and antiproliferative properties which can help prevent blood clot formation and cell overgrowth. CuSO4 is dissolved in water to create a copper solution.

• Silicone rubber – In this study, the chitosan and copper solutions were coated onto medical-grade silicone rubber discs to create the Chitosan-Cu coating. Silicone rubber is a flexible, durable material used for various medical devices including catheters. Other potential substrate materials for the coating include polyurethane, latex and other polymers used for medical devices.

To create the coating, the chitosan and copper solutions are mixed at different ratios (e.g. 10:1, 50:1, 100:1 chitosan:copper) and applied to the silicone rubber discs using an atomizer spray nozzle. The coating is then dried, creating a chitosan hydrogel film on the surface that contains copper ions at different concentrations depending on the solution ratio. The Cu2+ ions become embedded in the chitosan film as it dries.

The raw materials are all relatively inexpensive and simple to obtain and work with. However, preparing and applying the solutions at the right concentrations and ratios to achieve an optimal balance of antibacterial, anticoagulative and non-toxic properties in the coating requires careful refinement. The coating process will also need to be optimized for large-scale production and application to various medical device materials.

The use of simple, naturally-derived materials is an advantage for biomedical applications. However, controlling the properties and quality of the Chitosan-Cu coating will require precision in how the raw materials are prepared and combined. Regulatory standards for medical devices will also need to be met, requiring consistency in the coating composition and rigor in safety testing.

Does this help explain the key raw materials used to create the Chitosan-Cu coating and considerations for developing and applying the coating? Let me know if you have any other questions!

Here are some key advantages and limitations of the Chitosan-Cu coating:

Advantages:

• Antibacterial and anticoagulative properties. Potential to prevent infection and clot formation.

• Non-toxic. Low likelihood of damaging tissue due to low Cu content.

• Versatile. Can be applied to various catheter and medical device materials.

• Avoidance of pharmaceuticals. May prevent overuse of antibiotics and anticoagulants which can promote drug resistance.

• Extended device lifetime. Could allow catheters and implants to remain in use longer by reducing adverse events.

Limitations:

• Requires further testing. More research is needed to determine safe and effective ratios for different applications, and evaluate in clinical settings.

• May be difficult to apply uniformly. Spray-on coating must be optimized for large-scale manufacturing.

• Durability is limited. Coating may eventually wear off or come off, requiring reapplication. Permanent bonding to devices may be challenging.

• Ideal ratio is unclear. Balancing antibacterial activity and anticoagulation with safety and performance needs to be determined for different devices.

• Unknown long term effects. While non-toxic in short term tests, the impact of extended use or implantation is still uncertain, especially for Cu.

• Regulatory approval required. Extensive testing will be needed to gain approval for medical device use. This can take years and be costly.

• Competition from other coatings. Many other infection- and clot-resistant coatings are also in development and may prove more advantageous.

• Limitations for specific devices. While promising for catheters, usefulness for stents, sutures and other devices is still speculative depending on further research.

In summary, while this Chitosan-Cu coating offers significant benefits, there remain limitations from a lack of evidence for safety and effectiveness for medical device applications, as well as challenges in production, optimization and meeting regulatory requirements. Ongoing research can help address these limitations and determine where this type of coating has the greatest advantages compared with alternative solutions.

Right here is the right blog for anyone who would like to understand this topic. You realize so much its almost hard to argue with you (not that I actually will need toÖHaHa). You certainly put a brand new spin on a subject thats been discussed for years. Wonderful stuff, just great!

Itís nearly impossible to find educated people in this particular subject, however, you seem like you know what youíre talking about! Thanks